Water Well Pump Systems installations and Repairs

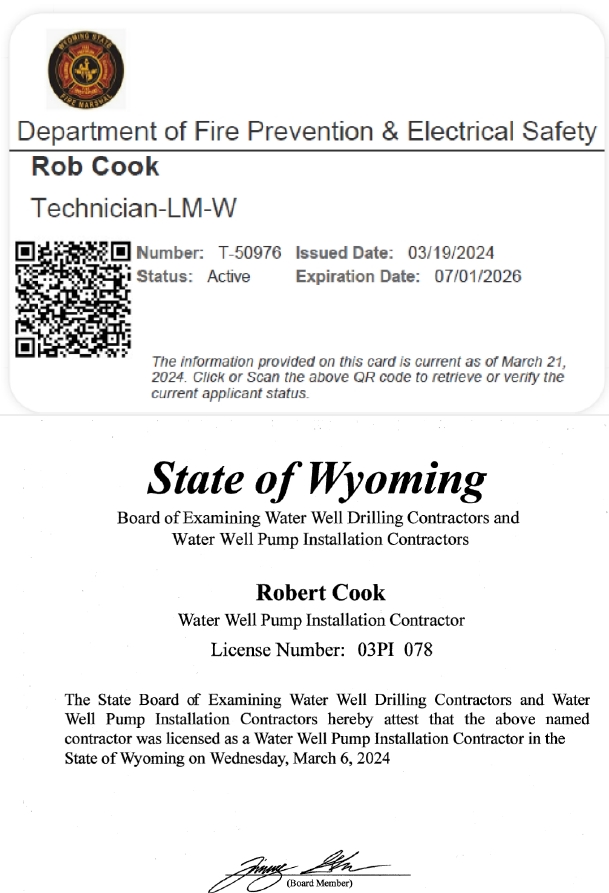

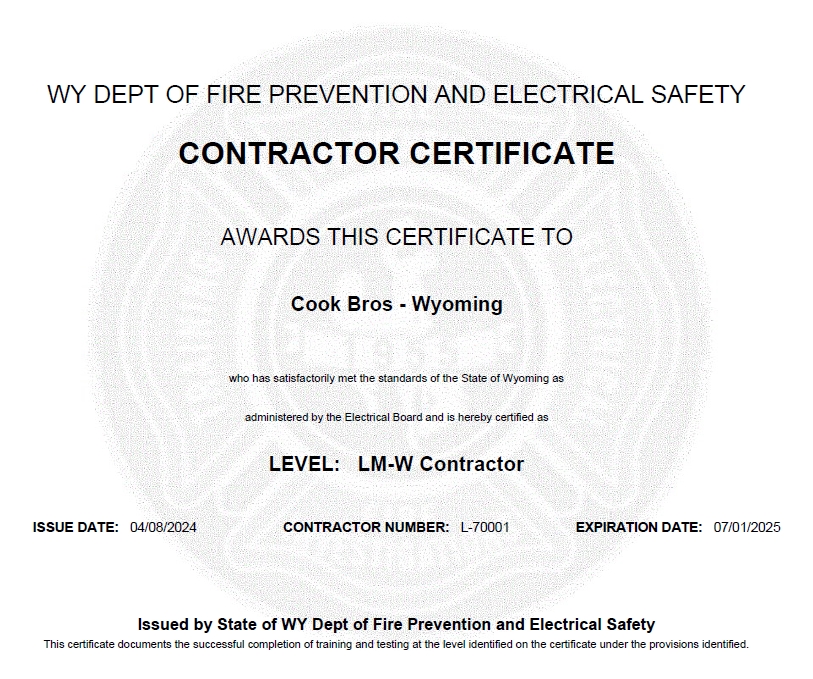

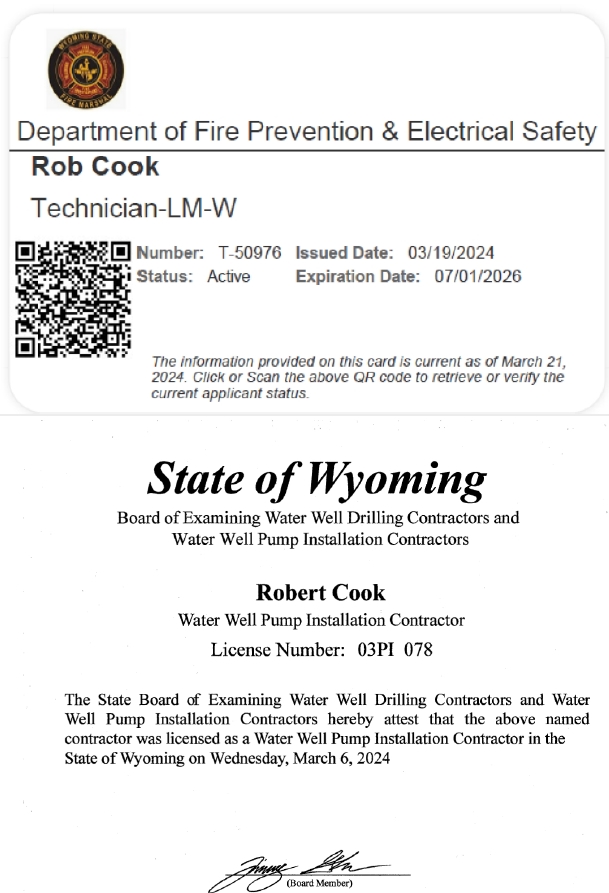

We are Licensed by Wyoming as Well Pump

Installation Limited Electrical Technicians

and Also as

Water Well Pump Installation Contractors

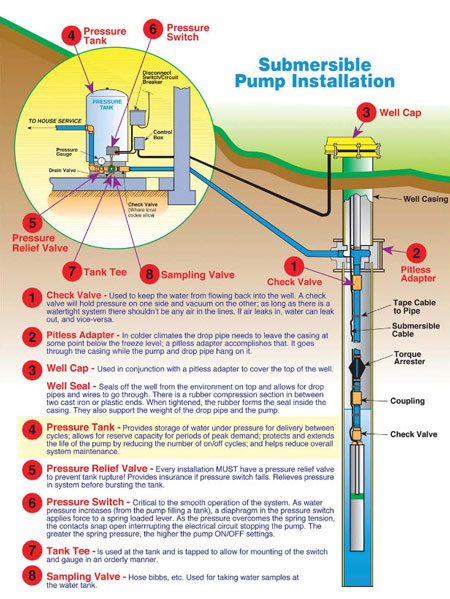

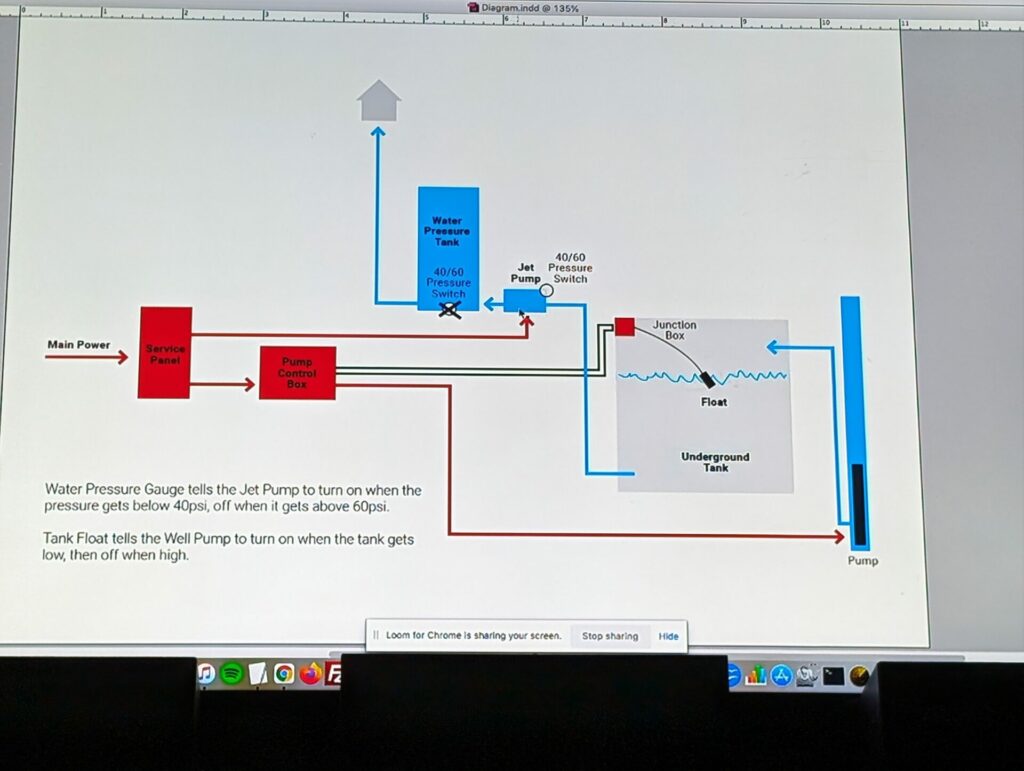

Water Well Pump Systems are a Complex Assembly of Components

Whether you have a newly drilled water well in need of a complete Pump System Installation, or the need for Pump System Service or Repair, Cook Bros. can help you.

When you do not have Flowing Water to your home or stock animals, the situation demands immediate attention. And not just a “Parts Changing” type amateur approach. We will work diligently to analyze your Well and Pump System and figure out what is the component(s) that is causing the failure. It is a system, a complex one with many parts and components that interact and are interdependent.

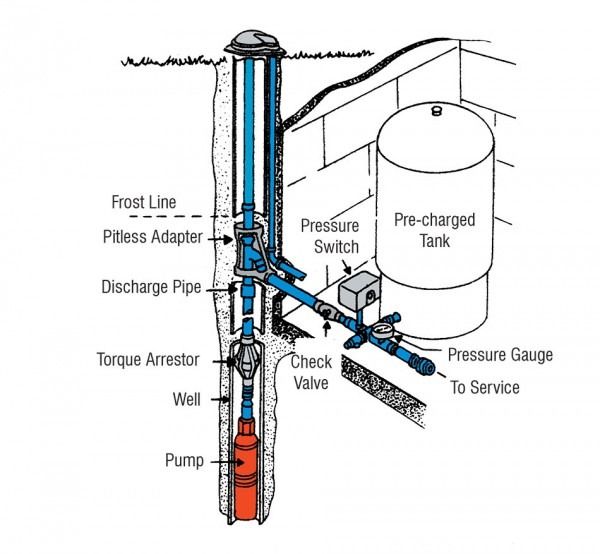

Water Well Pump Systems have many parts and components. They work as a system, and have to be tuned and adjusted and fitted to your actual situation and needs. One-Size does NOT fit all. In a typical Water Well Pump and Distribution system, you have Electrical, Plumbing and logical controller components.

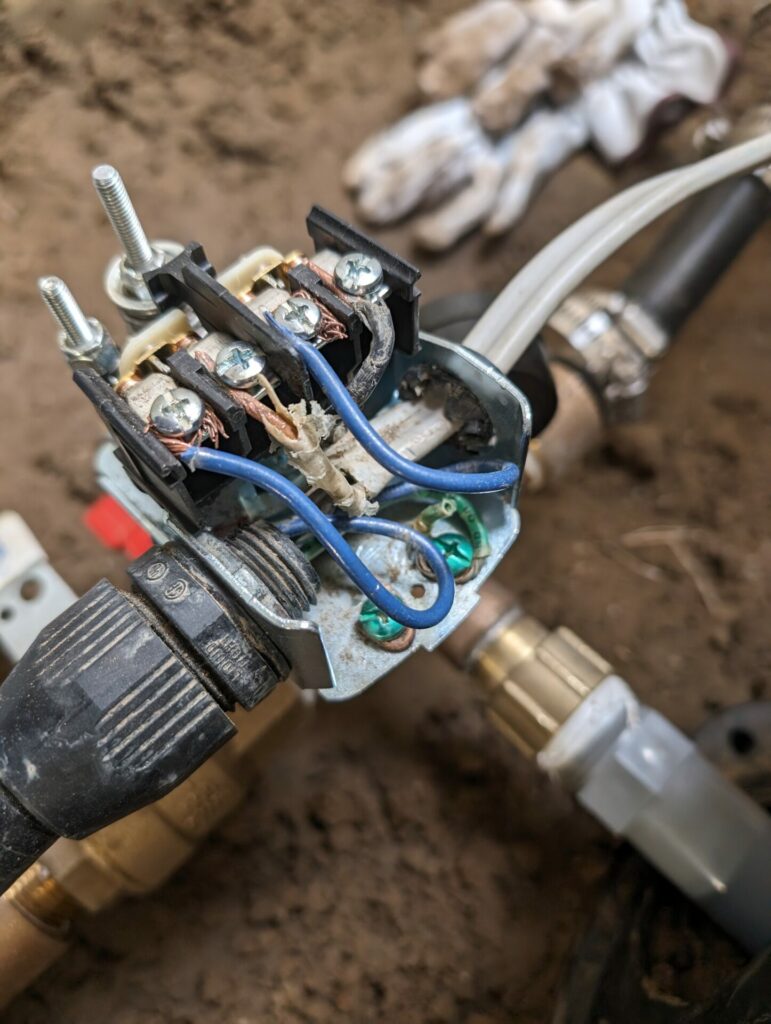

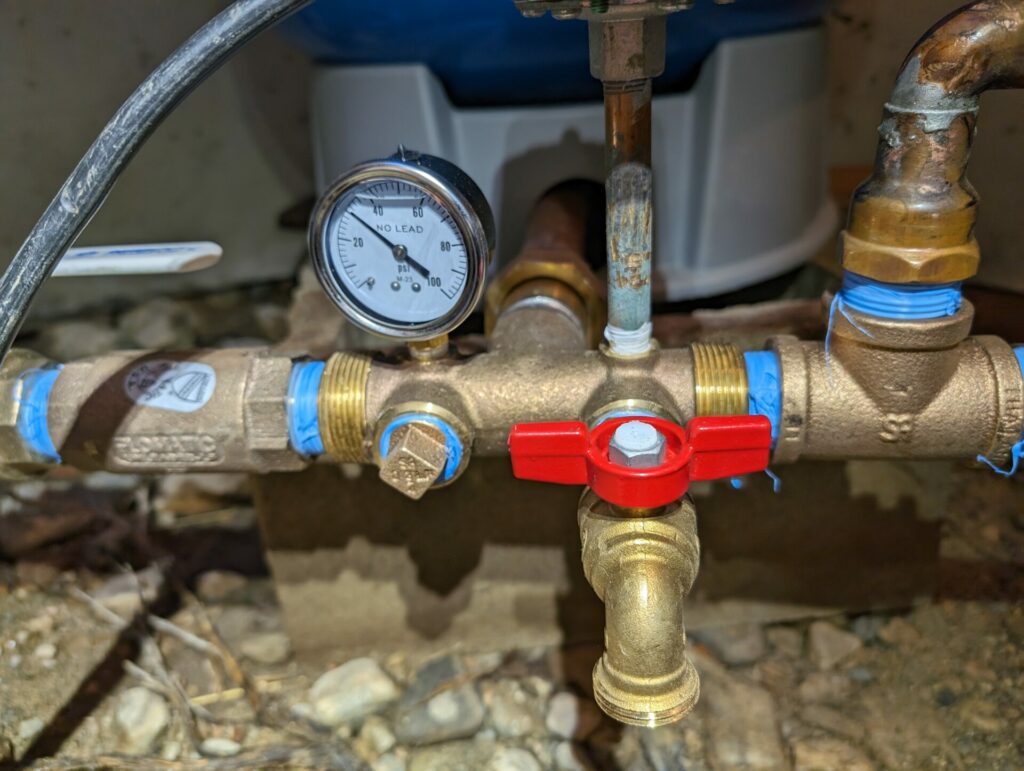

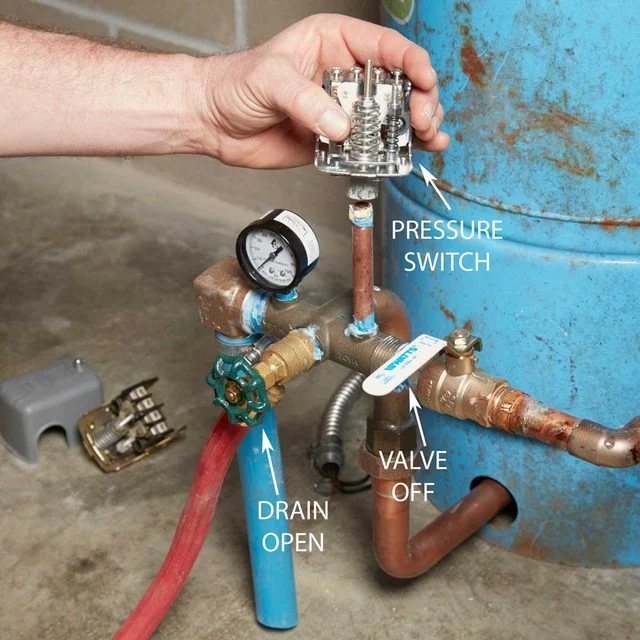

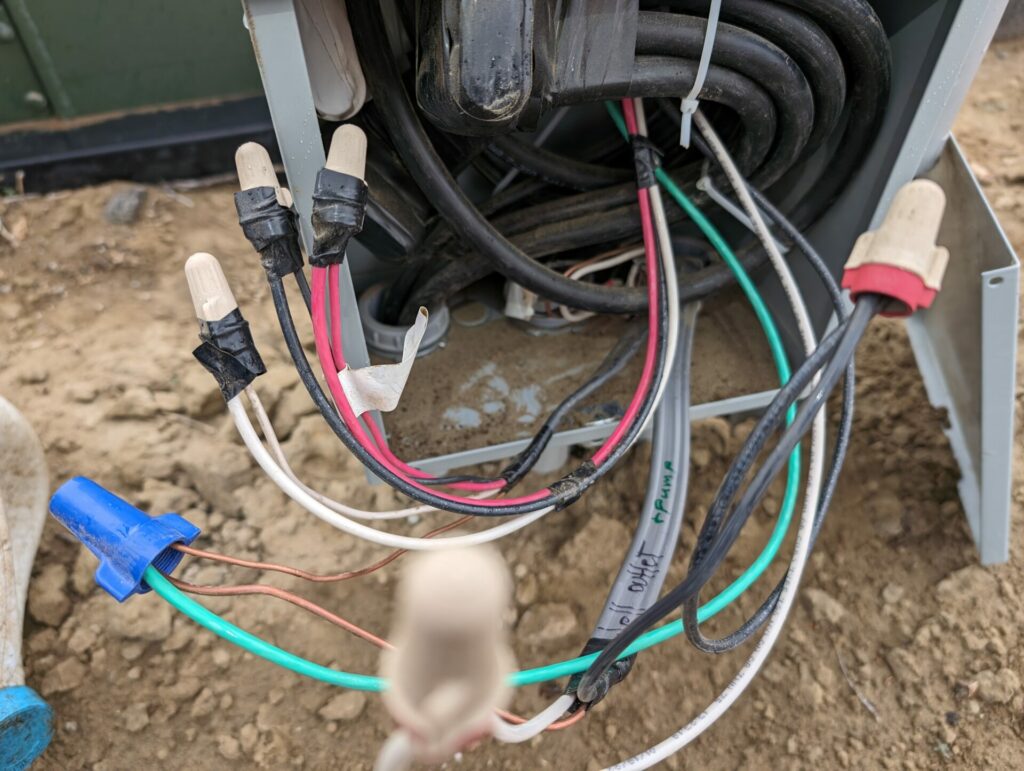

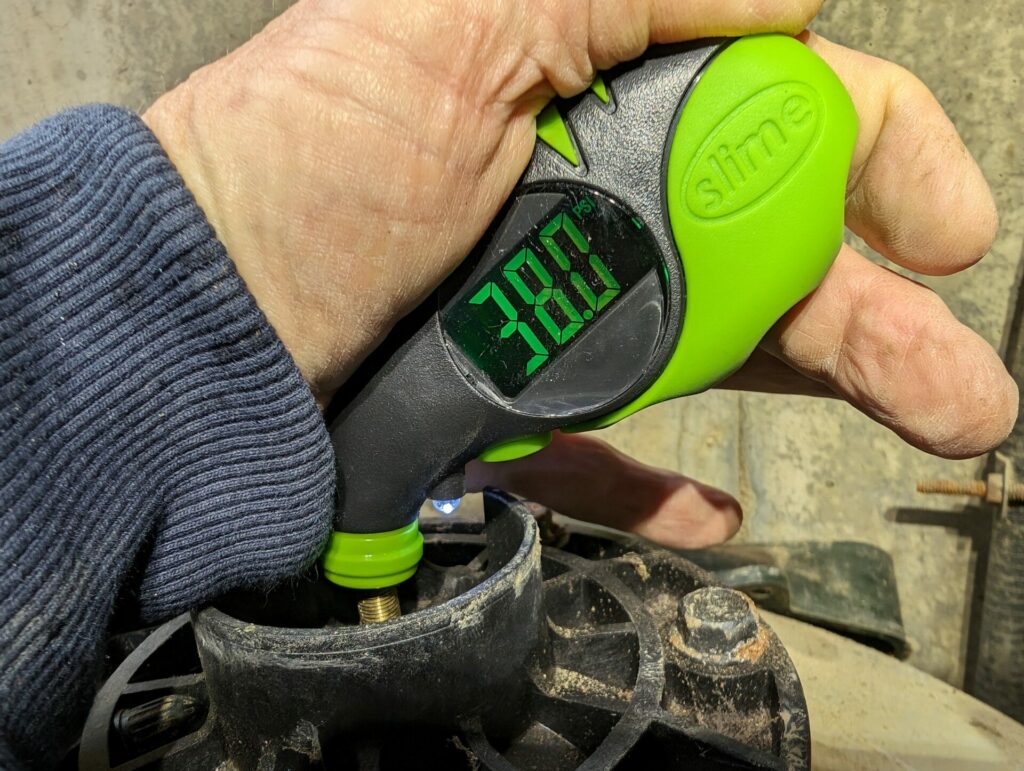

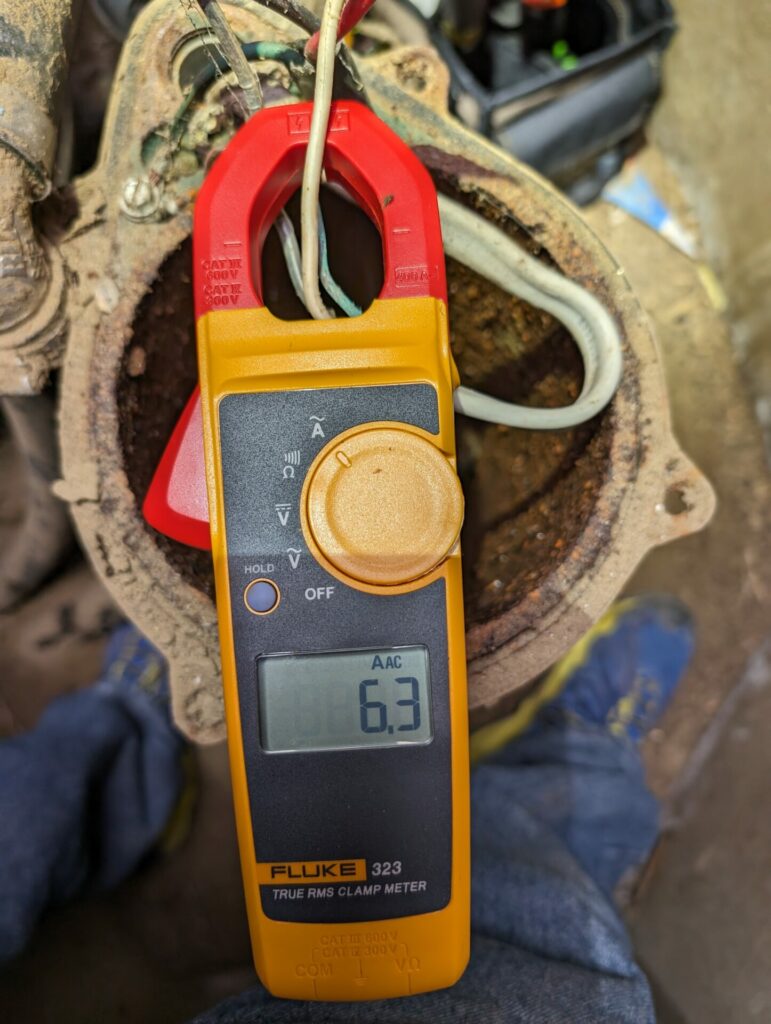

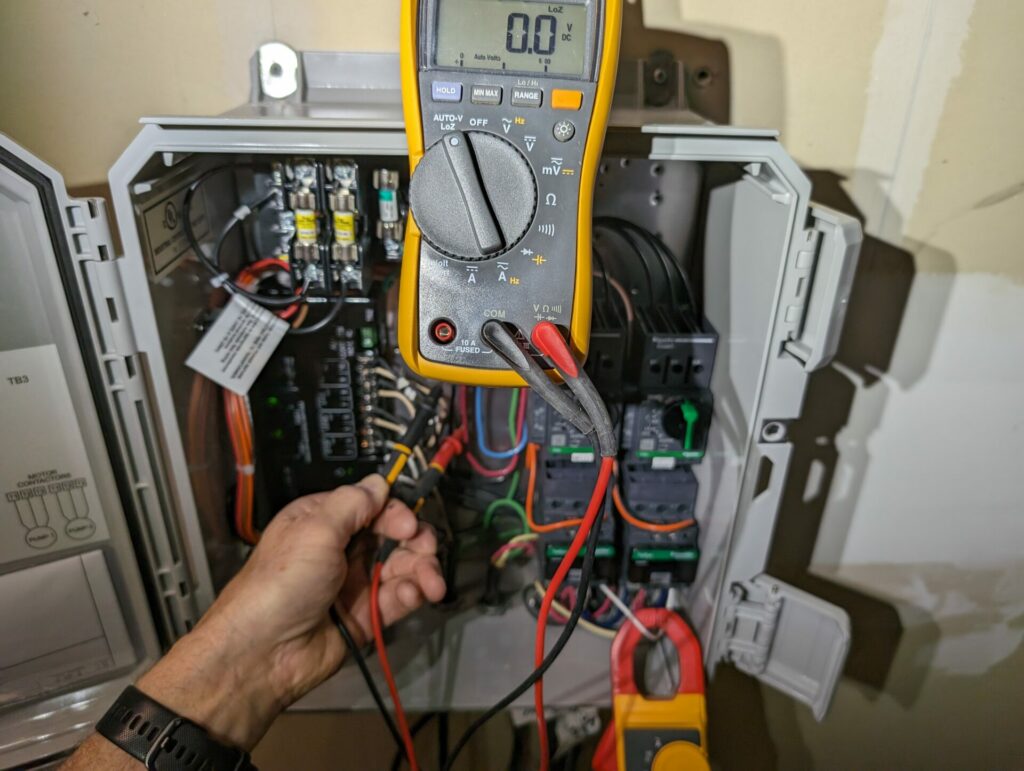

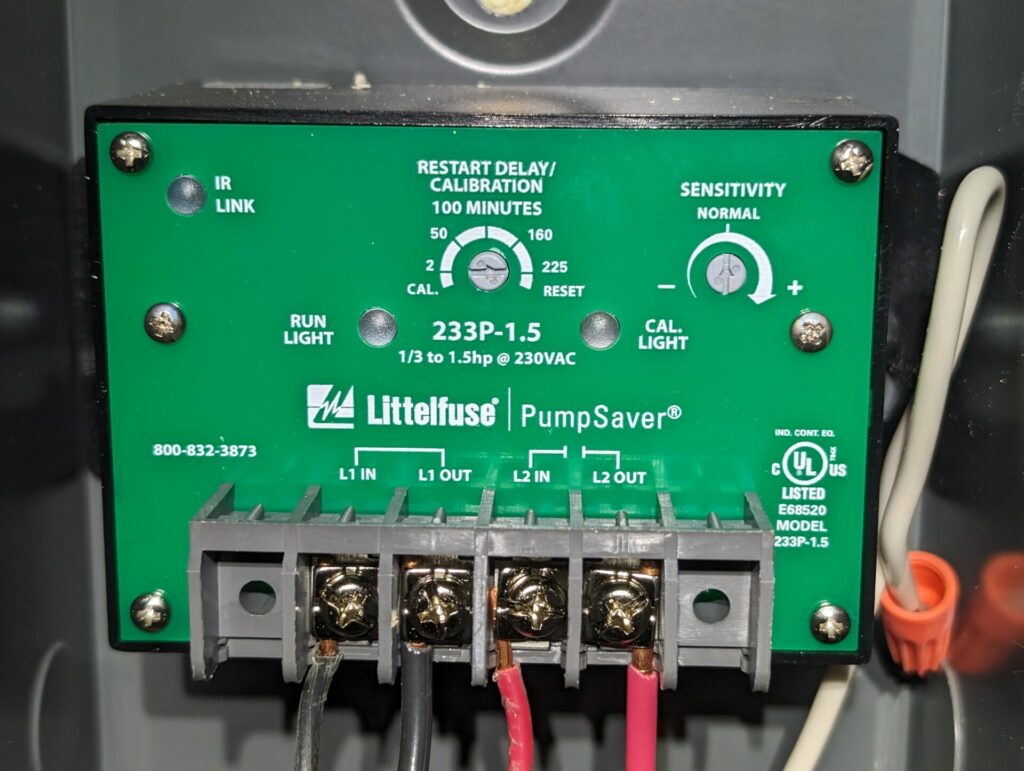

You have High voltage conductor wiring, of several varieties including submersible, buried and above ground in the controller and electrical supply on the load side. There are start/Run capacitors, Two and Three wire type motors and controllers, Single and 3-Phase supplies and motors, variable speed drives perhaps and motor protection, some built into the Pump motors, some external. And you have the Pumps themselves, Pressure Tanks, Pressure Switches, Filters, Valves and Gauges and distribution pipe to carry water from the Well Pump to the House or Stock Waterers.

That should indicate how complex these systems are, and how much knowledge and experience is required to properly, efficiently, effectively and professionally maintain, adjust, repair and install these Water Well Pump Systems.

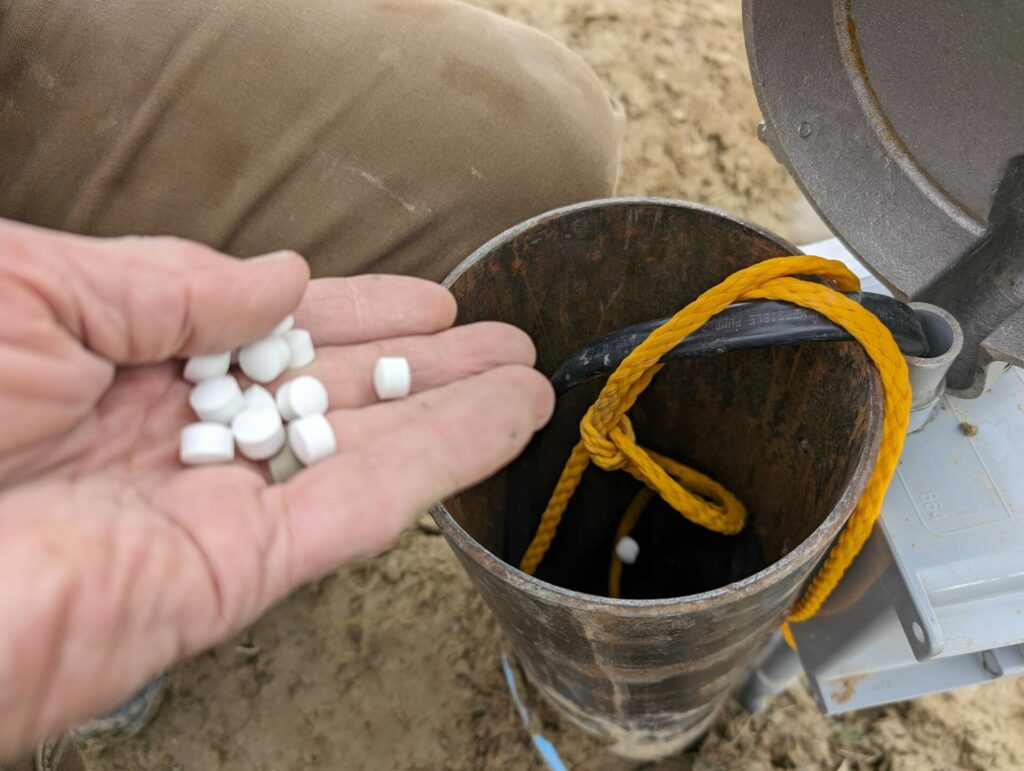

Preventative maintenance and regular annual/seasonal service attention will go a long way in extending the service life and efficiency of these Water Well Pump Systems, and head off the inconvenience and expense of “emergencies” by avoidable errors – premature failure.

Whatever you do, be sure to pay close attention to your water flow and the water volumes and pressure you are getting. And the water Aesthetics too, odors, color, taste and appearance of sediment. In this way you will possibly catch problems early before much if any damage occurs. Regular, Annual maintenance and inspection by a professional Water Well Pump Systems Installation expert is highly advised.

Fun Facts Which Actually Matter a Lot with Pump/Motors Systems

Fact #1: WARNING! It is illegal (a crime) for anyone not licensed by both Agencies of the State of Wyoming to perform any work on a Water Well, unless they own the well. Even a Licensed Well Drilling Contractor cannot alter, upgrade, repair or install any electrical or pump system related components UNLESS they also have the THREE licenses displayed above, which Cook Bros. Wyoming has. These laws are in place for very good reasons, to protect both the water well users and the ground water itself. Wyoming owns ALL of the groundwater, so they have the authority and responsibility to protect it from contamination or misappropriation, waste, etc.

Fact #2: Did you know that insulation on conductor wires, and in motor windings, has a lifespan? It does. ALL insulation and conductors and motor winding conductors do. They literally wear thin with age. So even though a motor appears to be running fine, it could be near its failure point as the insulation thins to the point of the potential to short circuit. Too-Thin insulation will not prevent an arc between adjacent conductors, a ground or other conductors in the motor winding circuit mass. Professional and Licensed Water Well Pump Installation Contractors use (Or SHOULD USE) a special insulation testing device called a Megohmmeters, which is not an inexpensive tool (ranging in price from $700 to $5,000). Just saying, would be nice for you to know how much of your pump motor and conductors lifespan has elapsed before you put an old unit or wiring back in the well. Might not be a bargain or savings at all, if all the labor has to be repeated in short order.

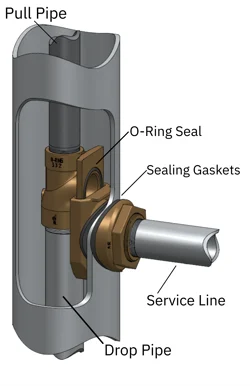

Fact #3: Be aware that the terminology used around the well pump and pump motor subject area can be misleading. People, even those in the business who should know better, call the submersible assembly they pull out of your well, the Well “PUMP. ” In fact, it is TWO separate components, which are connected together. A pump which is on the top of the cylindrical assembly, and the Motor which is on the bottom. Often the correct sizing and configuration needed for your well, has to be calculated based on many variables and the physics particular to your own well and site. This may require selecting a PUMP, and then a MOTOR, which can then be assembled to be your appropriate Motor/Pump solution. But even if a pre-assembled off the shelf assembly is used, it has to fit your particular hydraulic needs based on Static level of the water in your well, the pump set depth, the drawdown, the elevation of lift above the pump and static level and rise up to the utilization point, in your pump room of the house. Also the size and Friction of the drop pipe and the distribution line selected, and the Peak Demand of Water Flow required for your purposes. A LOT to consider and calculate to determine your appropriate well motor and pump.

Fact #4: Note that mis-sized or misadjusted components on ANY of the Water Well Pump System components, including the drop line, the Pressure Tank and the Pump motor and Pump, can result in Rapid Cycling or even Constant Running and inevitable premature failure of the pump motor, even if brand new. The pump turning on and off too frequently will result in heating up of the motor, and failure due to damage to the winding insulation.